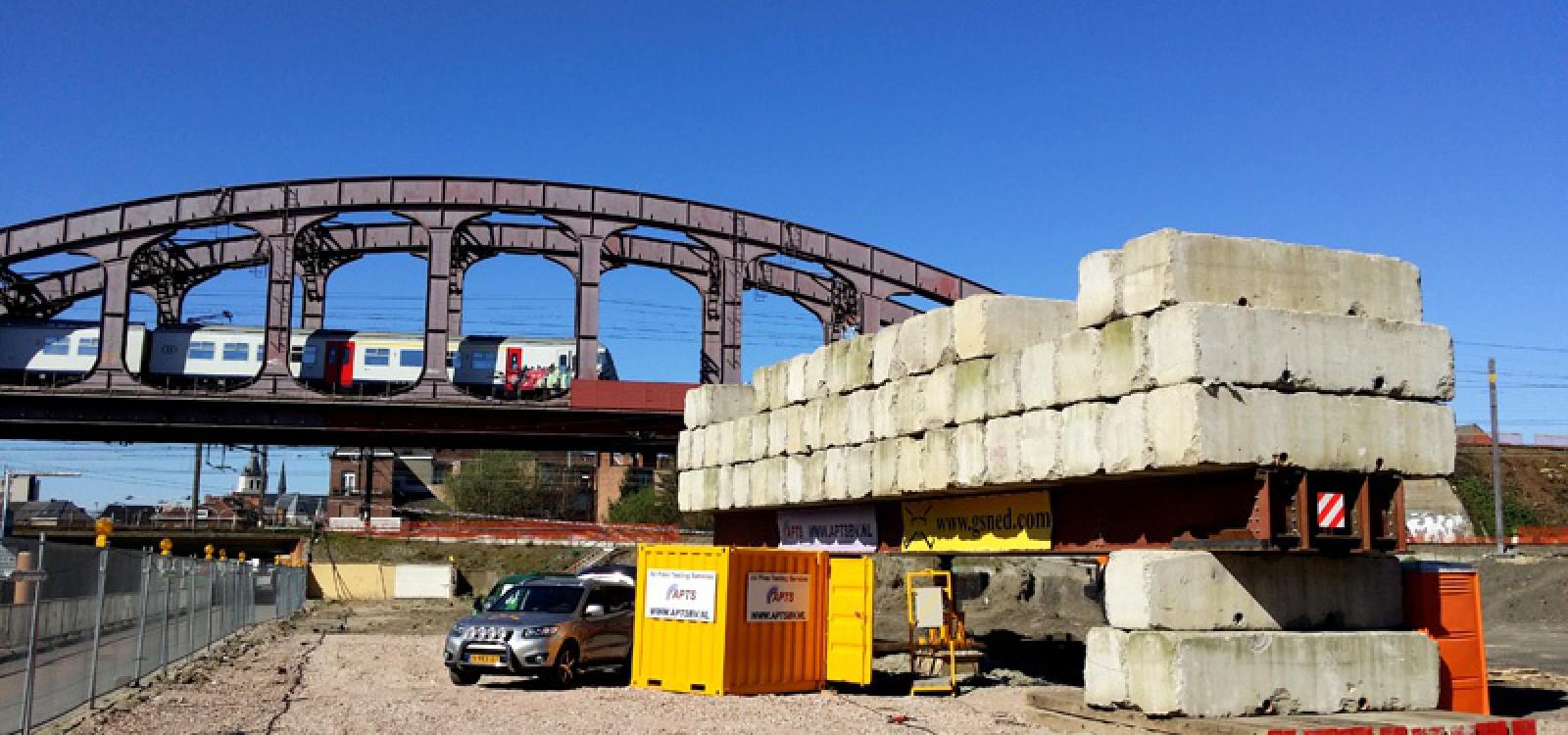

Galecopperbrug Utrecht (A12)

In the period 2013 to 2015 Rijkswaterstaat will renovate the Galecopperbridge, a part of the A12 near Utrecht. The Galecopperbridge is one of the 14 bridges within the project "Renovatie Bruggen". Like many other steel bridges from the 70s shows the Galecopperbrug fatigue. Like many other steel bridges from the 70s shows the Galecopperbridge symptoms of fatigue. Moreover, there is more traffic now than anticipated during the development and also the freight traffic has become heavier. With the renovation of the Galecopperbridge the vertical clearance for shipping at the Amsterdam-Rhine Canal also increases. Ships are getting bigger and carry more containers. In time, the entire route between the Rhine and Amsterdam must be made suitable for vessels with a maximum height of 9.10 meter, which allows four layers of containers to be transported. For this reason the Galecopperbridge is raised a few dozen centimeters.

Rijkswaterstaat commisioned contractor KWS Infra, part of Volker Wessels, to renovate the Galecopperbridge (A12). The renovation extends the lifespan of the bridge over the Amsterdam Rhine Canal with thirty years. The contract was awarded for an amount of approximately 80 million. The work is carried out under the name of "combinatie Galecom". KWS Infra cooperates with Mercon, Hollandia and CT-de Boer.

To confirm that the geotechnical load-bearing capacity of the foundation piles, and that the design meets the pile head subsidence after the provision of the piles is not greater than allowed, a pair of test loads is executed in order to verify the load-bearing capacity and the expected pile head subsidence.

APTS and BMNED/GSNED

These test loads are carried out by APTS, the alliance between Acécon Consultancy for foundation techniques bv, IFCO Foundation expertise bv and BMNED / GSNED. Two static pile tests are performed, ranging from 660 tons to 750 tons. Both pile tests are fully instrumented (Class A - strength and deformation controlled), whereby the load-subsidence behaviour, including the distribution of shaft friction and the force applied on the pile tip can be determined at at all stages of the test.

Facts & Figures

- APTS

- Kandt